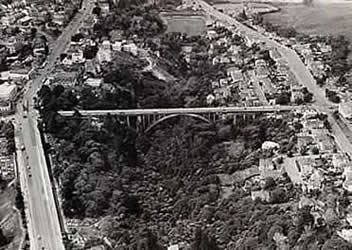

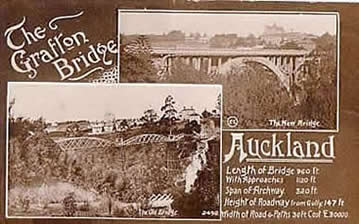

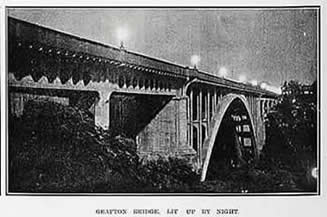

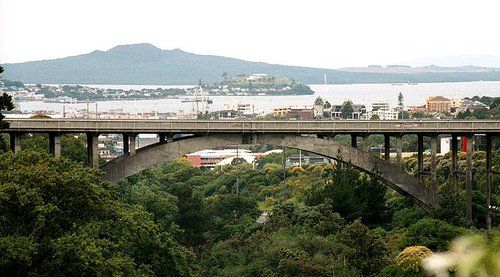

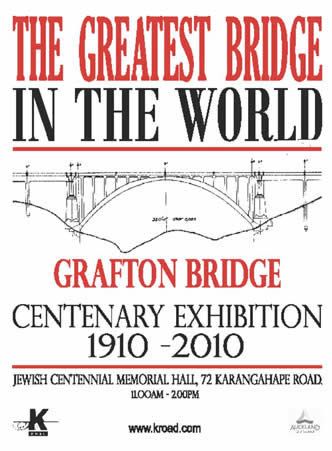

Grafton Bridge is a reinforced concrete bridge opened in 1910. It spans Grafton Gully which divides Auckland City and Karangahape road from the suburb of Grafton and the Auckland Domain. When it was completed it was the largest concrete arch bridge in the world.

1860s Map Central Auckland [left] Grafton Gully [centre] Domain [right]

The Auckland Domain is a piece of parkland laid aside by Governor FitzRoy in 1843, probably working from an idea of William Hobson. It was intended that this area would provide the new Capital with pleasure grounds and sports facilities. It is New Zealand's oldest Park. Initially called Auckland Park or the Government Domain, in 1861 it was formalised by Sir George Grey as the Auckland Domain.

In 1846 part of the area was set aside for the Hospital as it was within easy reach of the new town and faces north, enjoying views of the Waitamata Harbour, but isolated enough for quarantine reasons. Robert FitzRoy's grandfather was the third Duke of Grafton. The road leading to the park and hospital was given Grafton's name along with the new suburb which developed on the adjacent hilltop.

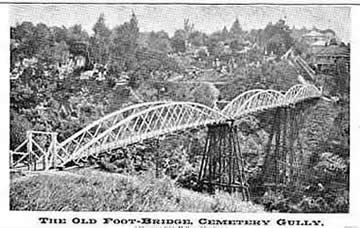

The adjoining gully acquired the same name although many people apparently continued to call it Cemetery Gully for some years. The gully wasn't very wide but was a definite physical barrier between the top of town and Grafton. By the 1880s it was apparent that some form of bridge linking the two locations was required.

J.G.Mitford Grafton Gully 1843 This view is taken from where Khyber Pass Road is now. The foliage shown here is probably manuka, Tree Ferns, cabbage trees and pittosporums. On the barren hillside [centre left] can be seen the gravestones of the Symonds street Cemetery.

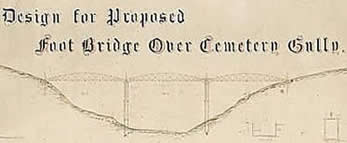

THE FIRST BRIDGE OF 1884

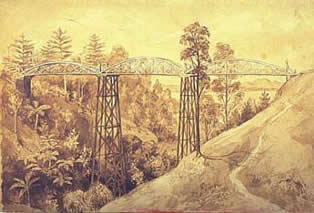

Design by William Anderson for the first bridge

The first bridge across Cemetery gully was a pedestrian bridge. Built of wood, probably kauri, and was designed in the form of a wooden trestle bridge. Designed by the City Engineer Mr William Anderson, probably with the assistance of Alfred Wrigg, it was constructed in 1884. The bridge was 360 feet long and rose 85 feet above the centre of the gully. Built by Messrs Larkin & O'Brien, it ran between the bottom of St Martin's lane on the west side of the gully to Bridge Street on the east.

Watercolour of the Cemetery Gully Bridge. The Cemetery Gully Bridge was opened by the Mayor William Waddel on the 9th of March 1885.

The new bridge could accomodate about three people abreast and was used by the residents of Grafton to reach Karangahape Road and by those visiting the Auckland Hospital on Park Road. As well as being the location of the Public Hospital, Grafton was the location of several private Hospitals and Rest Homes. With views of the harbour and the proximity of the Domain Grafton was considered a very desirable place to live.

In the 19th century the Auckland Domain contained several attractions including the gardens operated by the Auckland Acclimatisation Society which displayed newly imported plants and flowers. This was popular for family outings and for courting couples in particular. Other events were commonly held there as well such as Military Revues, Bicycle races, Balloon Ascents and Company Picnics. The Trestle bridge saw most use on afternoons when sporting events were held in the Auckland Domain. The Domain sporting fields were used for Rugby during the winter months and Cricket during the summertime.

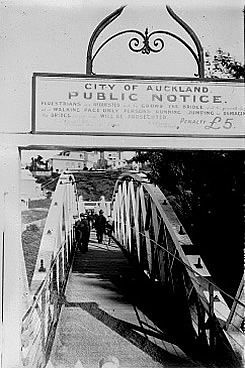

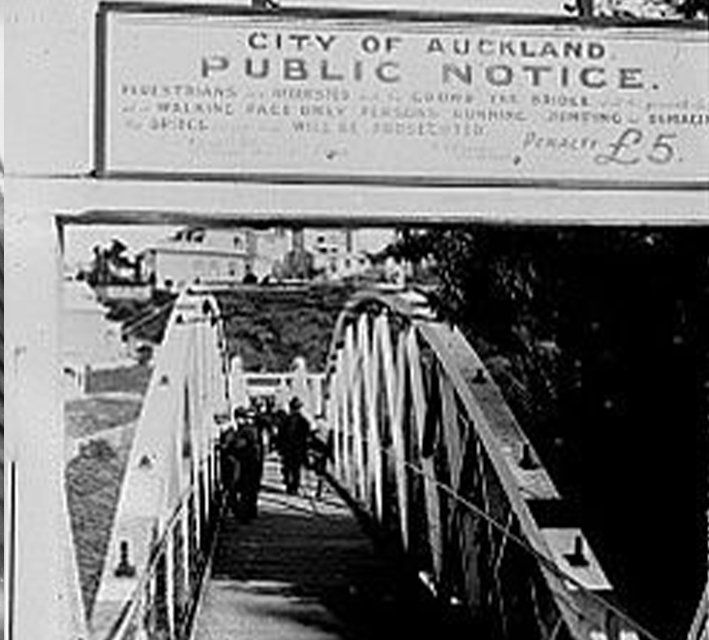

Notice forbidding running or jumping

Considerable numbers of people used the bridge on afternoons when sporting events were held; often filling the bridge to capacity. People began to notice the structure swaying and jumping which resulted in measures having to be taken. The sign pictured above admonished people against running and jumping.

As early as 1890 men were stationed at each end of the bridge on busy days to enforce the rules, but over the years concerns were voiced about the long term structural worthiness of the bridge.

For almost a decade the City Council largely ignored these concerns even when people began to observe that a general lack of maintenance including infrequent painting of the structure was allowing portions to rot or rust.

THE THIRD BRIDGE OF 1910

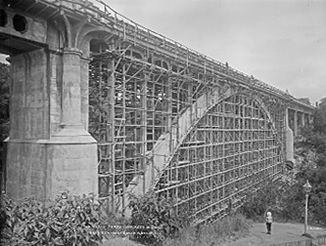

The bridge was designed and built by an Australian firm; The Ferro-Concrete Company of Australasia Ltd. Grafton Bridge took two and a half years to build, being opened in April 1910, and was claimed to be the biggest span, reinforced concrete arch bridge in the world at that time.

During Arthur Myers's Mayoralty Auckland had a population of 60,000 people. He fortold [correctly] that the population would double in twenty years time but few believed this possible.

Many thought that the city would never grow large enough to warrant the cost of such a large piece of engineering. The fact that a loan was taken out to pay for it meant concerns were raised that it would become a burden to successive generations of ratepayers.

Regarded by some as a profligate waste of ratepayers money many people called it “Myers Folly" for years. Myer's vision for a four lane bridge met opposition inside Council and it was eventually built as a two lane viaduct.

This has subsequently caused problems but it should be understood that had a four lane bridge connected K Road with Grafton then Park Road would carry a much higher amount of traffic. Today it would probably resemble Khyber Pass Road and the suburb of Grafton would be unrecognisable.

The Original Artist's Impression

Two tenders were received by the Auckland City Council in 1907, one in steel from the Messrs J. McLean & Sons for a steel bridge to be manufactured by the American Bridge Building Company for £28,730-12s 6d, the second for the reinforced concrete bridge for £31,918.

On the recommendation from the new City Engineer, Mr W. E. Bush, the concrete design was accepted, because the necessity of repainting would make a metal structure more expensive in the long run.

The choice of the more expensive tender aroused accusations of reckless spending from critics of the scheme both inside and outside council. As it happens a very similar metal design was constructed in Hamilton in 1911.

Victoria Bridge Hamilton

That bridge is of open spandrel construction, with a three-pinned central arch of 104 m and two approach spans resulting a bridge length of 152 metres. Designed by G. M. Fraser, the steelwork was prefabricated in Britain by the Cleveland Bridge Company, construction was supervised by James Fulton. Victoria Bridge Hamilton

AUCKLAND'S GREAT FERRO-CONCRETE TRAFFIC BRIDGE

From the 1910 Auckland Weekly News

The elevation drawing of the final design Note how the bridge slopes from west to east to aid drainage.

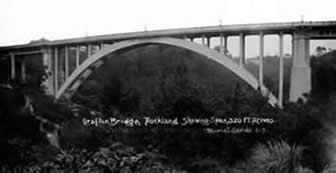

The bridge is 296 metres long. It is designed with a central span supported on parallel twin arches. The central span is 320 ft (97.6 m) wide, rising 84ft 9 (25.6 m ) above the abutments and attains a height of 142 ft (43.3 m) above the valley floor.

The design was the result of the work of Robert Moore (Chief Engineer), and Karl Rosegger (Chief Assistant Engineer), who made the calculations. The Bridge design is obviously influenced by several important bridges in Europe and the USA; the Howard Taft Bridge of 1897-1907 in Washington DC being just one example.

As the centre arch of the bridge would be the biggest in the world the specifications were submitted to Professor Moersch of Germany for approval. Moersch was arguably the world's most eminent expert on Re-enforced Concrete at the time.

The main piers are built

The concrete was made of beach shingle, in a 6 to 1 mix, using local cement manufactured by the Portland Cement Company.

Preliminary test of concrete were made by Professor Warren of Sydney and a design strength fixed at 500 lbs per square inch (3.4 mPa). William Henry Warren (1852-1926) was Professor of Physics at the University of Sydney and consulting engineer to the New South Wales Government.

Charles Rosegger and James Tyler explain about the concrete .

Formwork for the Main Arch

The timber formwork for the main arch consisted of 400,000 super feet (943 cu. m ) of West Australian jarrah and Oregon pine. This was a massive amount of water and rot resistant timber which had to be specially imported from Australia at no small expense. Difficulties arose for the Ferro-Concrete Company. The site, a steep-sided bush clad valley, proved more difficult than expected, with a combination of intractable clay and underground movement of water. There was also trouble with the complexity of the formwork and getting it in place. All this work had to be done by hand - the photographs do not show the use of cranes or hydraulic lifts.

Casting the Main Arch

The pouring of concrete for the main arch took 13 days Main Arch

All the 1200 tons of concrete for this project was mixed by hand and transported by wheelbarrels. As it happens the modern delivery system for concrete (Shotcrete) was being developed just around this time, but had not reached New Zealand.

Shotcrete, then known as gunite, was invented around 1907 by the American taxidermist Carl Akeley who used to fill plaster models of animals. He used the method of blowing dry material out of a hose with compressed air, injecting water at the nozzle as it was released.

In 1911, he was granted a patent for his inventions, the “cement gun", the equipment used, and “gunite", the material that was produced. In 1911 parts of the new Panama Canal were constructed using this revolutionary process which soon came into standard use. Grafton Bridge was probably one of the last large projects built using non-mechanised construction techniques. All the timber, steel and concrete used in the construction was moved within the site and fitted by hand.

Reinforcing steel being laid for the roadbed

AUCKLAND'S LANDMARK

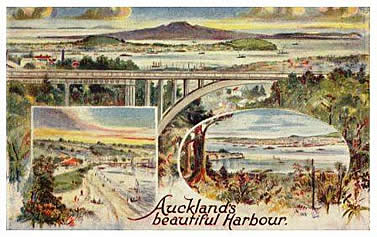

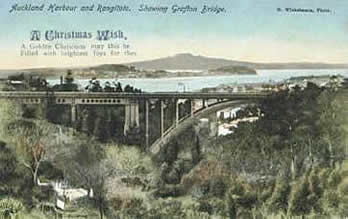

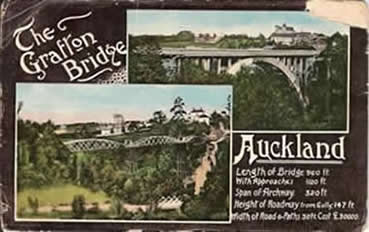

Picture Postcard depicting the bridge

To commemorate the opening, souvenir items in metal and china were marketed. The Bridge's elegant form is depicted in scores of picture postcards, immediately becoming one of the tourist sites of the city.

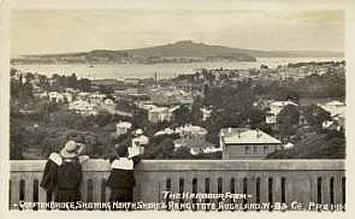

Grafton Bridge from Grafton Road and Bridge Street

At the time there were high hopes for the new “Electric Age" and the 20th Century in general. Until the following year when the new Town Hall was completed Grafton Bridge was celebrated as the greatest symbol of progress and civilisation in the province.

Even after it was no longer the largest single arch bridge in the world it was for many decades the biggest example of engineering in the country.

To this day the celebrated view of Rangitoto and the harbour from Grafton Bridge remains one of the charms of Auckland.

Christmas Card with image by the photographer, Henry Winkelmann.

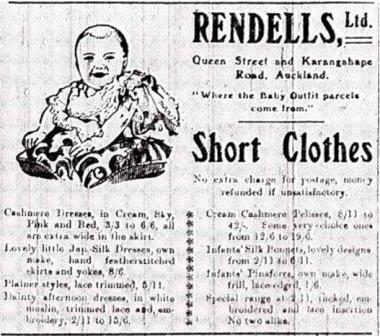

The construction of the bridge had a long-range effect upon the adjacent Karangahape Road. It is probable that the bridge was partly responsible for the upturn in retail activity on the street during the 1920s which was maintained all through the Depression and War years.

The Mesh Screens being installed 1957.

The Mesh Screens 1979

Despite objections from Healthcare Organizations, Auckland City Council removed the mesh screens from Grafton Bridge in 1996. Although the screens had not completely stopped suicide attempts for the previous sixty years they had prevented many people from ending their lives by this method. After the removal, suicide attempts from the bridge (both successful and unsuccessful) jumped five-fold.

Health Authorities lobbied for the replacement of the barriers but it took the Council until 2001 to initiate the project to build new screens. NZ Herald article:

Barrier to prevent suicides.

The Award Winning Glass Screens

In 2002 new Tempered-Glass Screens were installed at a cost of around $900,000. As well as deterring hamper suicide attempts the tempered glass screens also provide a modicum of protection for pedestrians from the weather. Although each set of Glass Panels appears uniform each member is actually slightly different. This is due to the slightly uneven construction measurements of the 1910 structure.

The new Glass Screens harmoise with the structure of the bridge very well combining the Art-Nouveau style with a modern aesthetic. In 2007 they received a Design Award.

On Monday October the 5th 2009 the bridge was reopened after being closed for reinforcing work. Reopening. Strengthening of the Grafton Bridge was carried out as part of the Central Connector Project, a 3 km bus rapid transit corridor connecting Auckland CBD and Newmarket via major destinations. It received a $7 million carbon fibre strengthening upgrade to bring it up to current Earthquake standards and to enable it to serve as a dedicated route for large numbers of buses. It can now accommodate up to 1200 bus trips a day. The bridge now has a load-carrying capacity of 40 tonnes, instead of the previous 13 tonnes. Installation of Reinforcement.

The work entailed each vertical member of the structure having four holes drilled from top to bottom to receive carbon-fibre reinforcing. This precision work was only possible using the latest computer technology. Drilling tolerances of 2mm/m were achieved.

Strengthening of Grafton Bridge

The project was very complicated but was actually completed three months ahead of schedule and almost a million dollars under budget.

Reopening Amanda Medcalf [wife of Mayor John Banks] cutting the ribbon to reopen the bridge on Monday October the 5th 2009. In attendance were members of the Grey family; who for the reopening ceremony provided the original sterling silver scissors used to open the bridge 99 years previously.

THE FERRO - CONCRETE COMPANY OF AUSTRALASIA

The Ferro-Concrete Company of Australasia was an Australian-based business, which operated mainly in New Zealand. Its parent company was evidently L.G. Mouchel (later L.G. Mouchel & Partners), founded by a major populariser of reinforced concrete in Britain, Louis Gustave Mouchel (1852-1908).

Specialising in reinforced concrete construction, the Ferro-Concrete Company held the licence in New Zealand and Australia to patents granted to Mouchel. Both Mouchel and the Ferro-Concrete Company were closely linked with methods developed by fellow French engineer François Hennebique. In 1897, Mouchel erected what is regarded as the first reinforced concrete framed building in Britain - Weaver's Granary and Flour Mill in Swansea - to Hennebique's design.

The Ferro-Concrete Company was evidently operating in Australia in 1902. It is reported to have been the first to undertake the construction of reinforced structures in New Zealand under the Hennebique system.

The company was responsible for initial large-scale modernisation of Auckland's waterfront in the early 1900s, including the Railway (later Kings) Wharf extension (1904-8), the Ferry Jetty (1907) and an initial portion of the Queens Wharf (1907-9). It erected other works in the same city including Liechtenstein's Building and a store for the Northern Roller Mills (1907-8), as well as structures in Napier, Hastings, and Wellington. It also built what was regarded as the first ferro-concrete wharf in Queensland at Gladstone (1907-8), and reinforced concrete wharves at Nukualofa (c.1906-7) and Neiafu (1908) in Tonga.

The company is perhaps most notable for the design and initial construction of Grafton Bridge, Auckland, at that time the largest single-span reinforced concrete structure in the world. The company, however, went into liquidation in November 1909. Some of the works that it was engaged in, such as Grafton Bridge, were taken over by other bodies. By December 1910, it had completed all of its contracts other than one that was sub-contracted. The company's final meeting of shareholders occurred in 1911.

Paperspast.

Auckland Star, Volume XXXII, Issue 44, 21 February 1901, Page 2

(.To the Editor.) Sir. -Cemetery Bridge! “Who is responsible for this structure? If it is unsafe for traffic, why is it not closed and put into proper repair? It is, I think, tho only bridge in Auckland, and evidently the authorities themselves consider it such a ginger-bread build that they will not allow a man or boy to walk over it. Further, the ladies and children are told to “break step," whatever that means. I consider whoever was responsible for the management of this tin-pot structure called a footbridge on Saturday last should have provided for males bom;; told at the top of tiie hill on either side that they were not allowed to cross, as it was, parties oj.1 ladies and gentlemen were separated, and many of them never saw each other again owing to the crowd in the Domain. The bridge should De strengthened or replaced. —l am, etc., A. EDWIN.

(To the Editor.) Sir. —On Saturday last a very large number of persons returning from the Domain availed themselves of the shortcut, to the city afforded by the Cemetery Gully bridge, your correspondent being one of the number, is'otwithstanding only a limited number of persons were allowed upon the bridge at a time, yet it began to oscillate to a frightful extent almost creating a panic amongst the female portion of the pedestrians. Fortunately a gentleman upon the bridge took in the situation and asked all those upon it to stop, which they did, until the oscillation ceased, I would suggest to the authorities that four steel wire ropes, two on each aide, be affixed to the bridge and securely anchored in the gully and properly hove taut. This would effectually cure the swaying- and render the bridge very much more safe for traffic than it is at present. —l am, etc. A STITCH IN TIME.

Eventually in April 1900 the Mayor asked the Government for expert advice on the state of the bridge! “A short time ago Mr D Goldie (the Mayor) wrote to the Premier asking him to appoint an expert in strengthening- bridges in the Government service to look over the local Cemetery bridge, so that measures might be taken to make it safer and to prevent it from swaying-. Mr Seddon has replied that the Mayor's request has been put before the Minister of Works for consideration." Amazingly it took another four years to properly address the situation. In 1904 the City Engineers department produced a report on the condition of the twenty year old structure.

Mr Wrigg's report came as a shock. The structure was working itself apart, the metal bolts rusting and several wooden members were rotten - in fact it appeared it was little short of a miracle it hadn't collapsed years before.

Had it done so, of course, it would likely to have been laden with sporting enthusiasts. By sheer luck, Auckland had missed a fairly major catastrophe.

“the city engineer reported that he had found the bridge to be worse than anticipated, being, indeed, absolutely unsafe for traffic. Most of the timbers were considerably decayed, and to repair it would mean practically a new bridge. The cost of repairs would not be less than £600 if the bridge was to be made safe, and probably further defects would be found as the repairs proceeded. In the circumstances he did not recommend that any repairs should be effected, and he did recommend that the bridge should be pulled down at once, to avert the great possibility that the bridge would collapse on some traveller beneath it without warning."

THE FIRST AND SECOND BRIDGES IN 1904

The temporary replacement bridge [presumably designed by Alfred Wrigg] was located right at the bottom of the gully spanning the tiny creek. For a while the first and second bridges stood side by side.

Pedestrian access to the second bridge required quite a descent down the side of the gully via a rough path and then up the other side. This was obviously inconvenient but it was assumed that the new replacement bridge would appear quite soon.

The Bridge in 1906 - Members of the public continued to use the old bridge despite it being closed off as a safety measure. It took two years to remove it.

The demolition of the old bridge 16th September 1906

The second bridge was intended as a temporary measure but due to the protracted process around deciding on the forum of the permanent replacement bridge it actually remained in use for six years.

During this period the small wooden bridge and the approaches to it were altered, wooden steps were constructed from Bridge Street and St Martins Lane.

“The track over the Cemetery Gully is now in excellent repair. A long series of steps leads down to and up from a little bridge over the bottom of the gully and foot passengers should be able to cross over dryfoot at all times. The walk is a very picturesque one but the romantic suggestion will not compensate the weary pedestrian for the loss of the bridge! “ Auckland Star 17 October 1904

The rebuilt Second Bridge The Third Bridge is under construction in the background.

There was quite a lot of discussion within Council as to what form the replacement bridge should take. Many progressively minded people, Arthur Myers included, wanted a bridge which carry vehicle traffic.

A number of people inside and outside the Council resisted the extra expenditure this would entail and argued for another pedestrian bridge. “A Low level steel bridge over cemetery gully would cost £18,500, high-level £24,500. The cost would be less if wood were used" Auckland Star 19 May 1904 Eventually the progressive option of a vehicle carrying viaduct, as championed by Myers, preveiled, although the design of the bridge was cut back from four lanes to only two. Letter

Although the Third bridge was swiftly built, construction on it only started in 1908 and so the second bridge was the only public way across the gully from 1904 until April 1910.

1909 CRISIS

Halfway through construction the Ferro-Concrete Company was declared bankrupt. This situation was directly attributable to the contract clause which stipulated that “…no progress payments should be made on the arch span till it is completed and tested." It is uncertain whether this clause had originated with Professor Moersch or within the City Council but it led to devastating consequences for the project.

Usually Progress Payments are made to a contractor as each segment of a project was completed and signed off. On this project two major stages [creating the foundations and constructing the two Approach Spans] should have meant the Ferro-Concrete Company could pay off it's suppliers and workforce.

The completed bridge

By deferring any payments until the Main Arch was completed and structurally tested meant the Company simply ran out of money. The inability to pay it's workers or suppliers effectively meant it couldn't begin to construct the main arch. The Ferro-Concrete Company of Australasia went into liquidation in November 1909. The project had to be completed by council labour, supervised by the City Council Engineer W.A.Bush. This was problematic as his attention was thus diverted from other council projects. The house at 123 Grafton Road was rented for Bush to reside in for the duration so he could be readily on hand day and night.

The clause in the contract had been included as an inducement to make sure the company produced a quality product for Auckland City Council. It actually destroyed the Ferro-Concrete Company and imposed the construction of the hardest part of the structure onto the Council itself. The final cost for the bridge was £35,000 because of a cost over-run of £3,000 or 9.5%.

Deadload test using gravel

In March 1910 Load tests were carried out on the newly-completed bridge using gravel. Firstly one half of the arch span was loaded with 292 tons (297 tonnes) of roading aggregate, giving 113.5 lbs per sq ft (5.4 kPa), and the deflection measured as only 1/8 inch. (3.17mm)

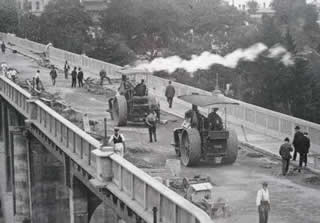

The Steam Rollers

When the road metal load was removed, two steam rollers, of combined weight 32 tons, were run over the bridge and the deflection was measured as 1/12 inch (2.12 mm). These results were deemed “extremely satisfactory"

The completed roadbed

The Bridge was informally open for pedestrian traffic as early as March 1910 while the finishing touches were made to the roadbed, balastrading and the new toilet block, which was the first to include facilities for women.

View showing the broad roadway The absence of Lamp Stands means this view dates from before April the 21st 1910 when the Electric Lights were fitted and tested.

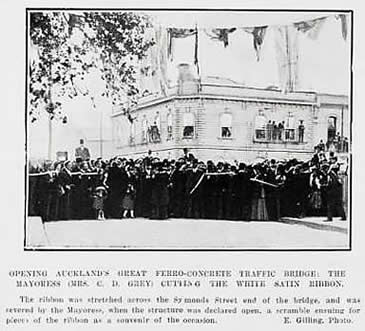

THE OPENING CEREMONY

The Opening Ceremony was held on Thursday 28th April 1910.

The Opening 1910 The Karangahape Road end of the bridge at 3 o'clock.

The Ceremony was marked by three speeches; firstly the outgoing Mayor Charles Grey, then Arthur Myers [the previous Mayor] and then Mr W.A.Robertson of the Ferro-Concrete Company of Australasia.

The inclusion of Mr Robertson of the Ferro-Concrete Company was especially significant - he made no allusion to the 1909 crisis and the subsequent bankruptcy of his company - instead he praised the Council for their vision and commended the City Engineer W.A. Bush for his role in supervising completion of the project.

In attendance were the Governor of New Zealand, Lord Plunket [who had laid the Foundation Stone] and the Prime Minister Joseph Ward, neither of whom made speeches. With them were the Mayor elect Lemuel Bagnell, Mrs Arthur Myers, Charles Rosegger and the City Engineer W.E.Bush. NZHerald

“A large crowd listened to long speeches from the Mayor and Mr Arthur Myers, from the bridge committee,- and the contractors, and even became enthusiastic enough, to cheer every now and again."

Following the Official Speeches, the Mayor's wife, Mrs Grey was presented with silver Scissors by the City Engineer W.A.Bush and opened the bridge by cutting the white satin ribbon. The Mayor and Councillors then drove across the bridge in carriages followed by a proportion of the crowd. Views on the Official Opening:

People crossing the bridge People returning from a Review of Cadets before Lord Kitchener in the Auckland Domain on March 1st 1910.

Colour Postcard showing all three bridges

The Symonds Street Entrance with the Public Toilets

On either side of the Symonds street entrance to the bridge are four piers each with a bronze commemorative plaque. These denote:

- The Laying of the Foundation Stone by Lord Plunket

- The Opening of the Bridge by Mayor Grey

- Those responsible for the Bridge [including Myers]

- The Pioneers whose graves lie next to the bridge.

When the bridge was constructed, the cemetery had been in existance for seventy years. It was Lord Plunket who suggested the inclusion of a plaque to remember the dead.

THE EFFECT OF GRAFTON BRIDGE:

K Road had been an important shopping area before 1910 but after the completion of the bridge in 1910 and the Auckland Exhibition of 1913 it developed into Auckland's main shopping street. The effect of Grafton Bridge.

Karangahape Road maintained this status until the 1960s when the construction of the Auckland Motorway System and the advent of suburban shopping malls altered the retail landscape of the city.

THE LEGACY OF ARTHUR MYERS:

In 1921 Arthur Myers retired from politics and he and his wife made plans to retire to London (where his wife was from). This resulted in much comment in the media about his contribution to the Public Good, both in Auckland and on a National Level. A commemorative dinner was held and he was presented with a Silver and Gold trophy as a reminder of his contribution to the progress of Auckland City. This took the form of a model of Grafton Bridge as it was considered the most important example of his work. The fact that Grafton Bridge was chosen ahead of any other project to serve as a symbol of his contribution is significant.

Silver and Gold model of Grafton Bridge presented to Arthur Myers in 1921 Made by Charles Cowen in the workshop of A.Kohn 48cm long, 6cm wide, 11cm tall Kauri wood base with Greenstone and Kauri Gum. The Myers relocated to Britain in 1921, he was knighted for his Public Service in 1924 and died in London in 1926. His business concerns in New Zealand were left in the hands of his son Kenneth Myers and eventually his grandson Sir Douglas Myers.

RECENT HISTORY:

Grafton Bridge was used by many individuals for suicide attempts, eventually in July 1937 a safety fence was installed to hamper such events. This was disparagingly termed “unsightly chicken netting" by one ratepayer.

The structure of the bridge apparently required little or no maintenance for over twenty five years but in 1936 some cracks that had been observed for some time became worse and “ a considerable piece of concrete became detached and fell away from the bottom chord……. of the span adjacent to the main arch at the Grafton Road end." The City Engineer, A.J.Dickson, prepared a report on the damage.

The Vierendeel Beams

This view shows the octagonal openings which were filled in in 1938. The study showed that the shear stresses in the Vierendeel frames was excessive and there was surprise that the structural performance had been as good as it had been. The remedy was to erect two steel trusses on the deck to support the damaged area. The octagonal openings were filled in and are no longer a feature of the bridge. These repairs cost £21,800. After this point there was a weight limit imposed on traffic using the bridge, even during the Second World War the large trucks used by the US Forces stationed in the Camp located in the Domain were not allowed to drive over Grafton Bridge.

Further reinforcing was carried out in 1957 which is also when the Suicide Screens were replaced.

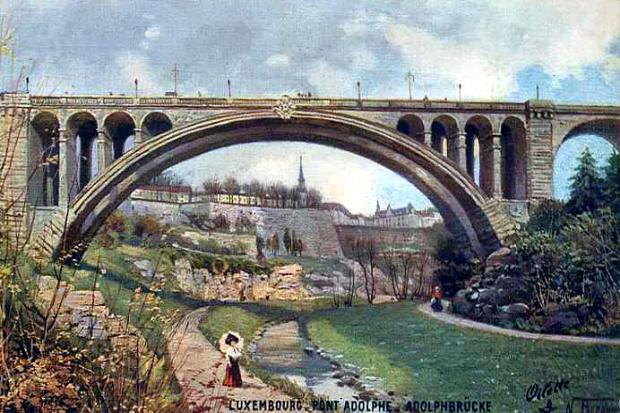

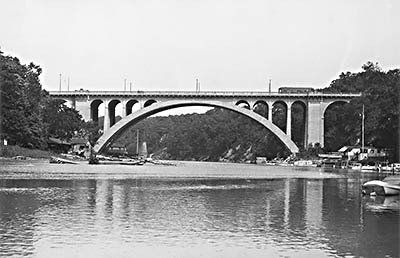

CONCRETE ARCH BRIDGES OF THE PERIOD

277ft - 84.65 metres.

1900-1903 - PONT ADOLPHE Luxembourg By Paul Séjourné

Pont Adolphe Reinforced concrete and stone.

320ft - 97.6 metres.

1908-1910 - GRAFTON BRIDGE Auckland, New Zealand. By Robert Forbes and Karl Rosegger . Grafton_Bridge Reinforced Concrete. Opened April 28th 1910 as the largest concrete arch in the World.

280ft - 85.344 metres

1908- 1910 - ROCKY RIVER BRIDGE Cleveland, Ohio, USA. By Alfred Felgate and Wilbur Watson. Rocky River Bridge article Concrete but not reinforced.

Opened October 11th 1910 as the largest concrete arch in the World.

281ft - 85.6 metres

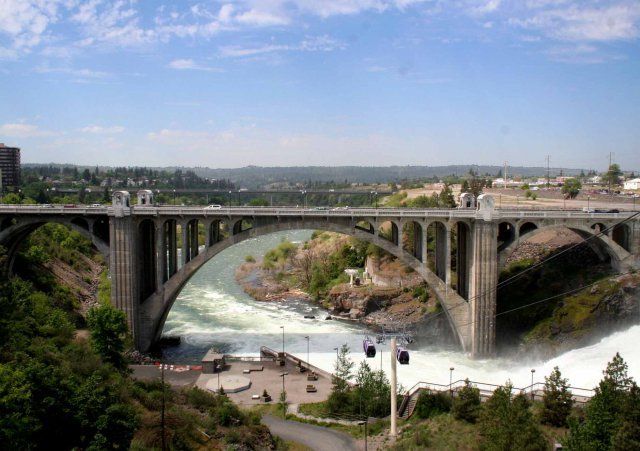

1911 - MONROE STREET BRIDGE Spokane, Washington, USA By John Chester Ralston & Kirtland Kelsy Cutter. Monroe_Street_Bridge Reinforced Concrete.

328.1 ft - 100metres

1909-1911 - PONTE RISORGIMENTO Rome, Italy. By Giovanni Antonio Porcheddu

Risorgmento Bridge Reinforced concrete and Stone

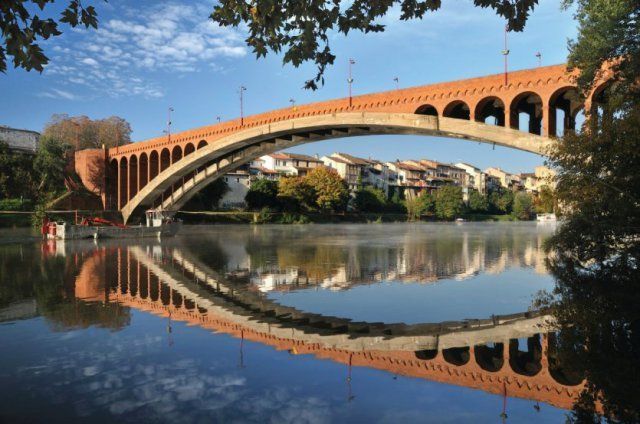

315.78ft - 96.25 metres.

1910 - 1919 - PONT DE LA LIBERATION Villeneuve-sur-Lot, France. By Eugene Freyssinet.

Pont de la Liberation Reinforced Concrete.

Subscribe to the

Karangahape Road newsletter...

NEWSLETTER

Thank you for signing up for our newsletters.

Please try again later.

Karangahape Road Business Association © All Rights Reserved 2020

Made by Monster Valley & This Needs Doing

AUCKLAND TRANSPORT JOURNEY PLANNER:

Find out your best route to Karangahape Road by bus, ferry or train.